Every small action optimizes your performance.

OPERATIONS

We lead organizations to the synchronization of their strategic goals with daily operations.

THE BACKGROUND.

Companies’ quest for profitability drives the implementation of agile methodologies based on the principles of continuous improvement. Manufacturing companies are faced with the challenge of constantly checking their processes to ensure efficient operations, optimize costs, ensure product quality and achieve service excellence.

Being deficient in risk management while continuing day-to-day operations exposes the organization to potentially very serious damage: whether it be disruptions in the production process, property or operational damage, or failure to deliver promised services to customers, these eventualities must be anticipated and averted.

4:1

~60 days

Management & Team

most common challenges

In most manufacturing sectors, the entire supply chain is under new, growing and highly complex pressures that need to be managed. The pursuit of sustainability, the adoption of increasingly lean supply chain management models, and the ever-higher standards of human resource management are all increasing complexities in day-to-day operations.

Organizations are challenged to keep up with these socio-economic trends to remain attractive, but the real challenge is to do so while maintaining profitability or, even better, increasing market share through outperformance over competitors.

Finally, it should be added that the rate at which these trends emerge and the urgency of their application are both increasing: there has never been a greater need for companies to be able to maintain flexibility and high standards and to innovate and renovate with readiness and determination.

OUR SOLUTIONS

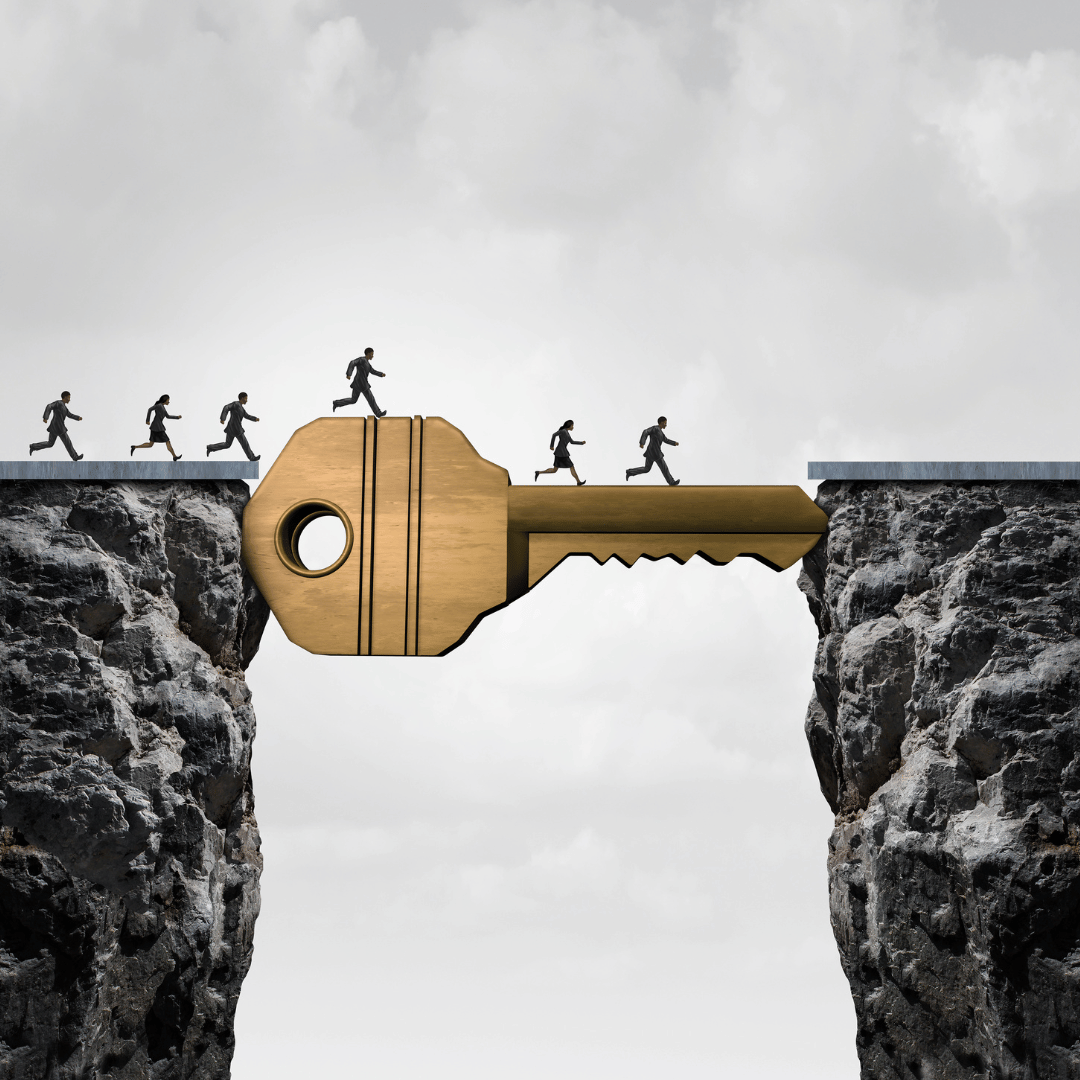

In a context so opposite to the business-as-usual concept, we focused our efforts on developing an intervention method capable of impacting in two complementary and mutually enhancing ways:

- “Hands On” approach

Intervening in an organization today, maintaining operations and continuing to meet commitments, requires the ability to change on the run. This is not an easy challenge, but thanks to experience and thorough auditing and oversight processes, we are able to start our projects with high-impact key interventions. - Mindset and Consolidation

Once the initial shock has passed, it is critical that “the outcome outlives the consultant.” Too often we have heard of interventions that have completely lost their effectiveness once the external team, the one that in theory would be supportive, has left the operational area. On the contrary, our work is developed in a path made to train and educate the resources involved, so that new processes and methods are complemented by mindsets and soft skills that can consolidate the result.

THE IMPACT

Discover the stories of those who have already trusted us to gain greater control over their operational risks

Stratega took part in the consultancy activities for a French newsprint paper manufacturer facing increased demand and operational uncertainties leading to potential losses and inefficiencies. Within a tight timeframe of less than a week, Stratega identified four key areas for improvement. As a result, the printing house achieved a remarkable 20% reduction in operational costs through improved efficiency and supply management.

Questo articolo discute le strategie per ridurre i costi di produzione, inclusa l'ottimizzazione dei processi, il miglioramento dell'efficienza e la ricerca di materiali e servizi.

This article discusses strategies to reduce manufacturing costs, including process optimization, efficiency improvement, and materials and services research.

Risk is inherently unpredictable; the ability of the risk manager is demonstrated through the creation of potential solutions capable of keeping the achievement of the set goal intact.